GCS RAMS certificate

is a must for any director, manager, integrator, design engineer, development and test engineer, customer support or maintenance engineer.The applied workshops are advocating a transition towards a reliability-focused culture, covering the entire life cycle of a product from inception, through engineering design and validation, manufacture, to entry into service and disposal.

The certificate is the initiative of Dr. Sorin Voiculescu, Lecturer at Concordia University Gina Cody School of Engineering and Computer Science , reliability Ph.D., former Reliability Specialist with Bombardier Aerospace, CSeries (A220) program.

RAMS or R-AM-S?

RAMS engineering: Reliability, Availability, Maintainability and Safety engineering across the lifecycle (concept, design, validation, operation, disposal) of a product, are the foundation of the improvement initiatives that can deliver substantial financial and other major benefits to any Organization and to the Society.In an economy confronted with a major waste issue at a planetary scale, the design for reliability (DfR) should play an important part in the envisioned plan to keep under control the waste produced by products reaching their end-of-life and to reduce the greenhouse gas emission generated during recycling. On a separate topic, the increase in the rate of technological change (accelerating change) increases the risks on consumer safety. So, RAMS.

For large organizations, we shift towards R-AM-S: Reliability, Asset Management & Safety. These are major contributors to the achievement of the United Nations' Sustainable Development Goals (SDGs) #3, #6, #7, #8, #9, #11, #12, #13 and provide the tools and the management system to ensure that good intentions are turned into reality. So, R-AM-S.

Our ultimate goal is to offer a better world for the future generations to come.

AM: Asset Management

Asset Management– does not focus on the asset itself, but on the value that it can provide to the organization and its stakeholders

– is business/purpose-centric, NOT asset centric

– is a philosophy to the way to do business – it is not a new silo in organization!!

Asset Management focuses on Total Business Impact - Where to spend your last (or first) $$ ? People and organizations have been caring for assets since mankind first invented tools.

Managing Assets vs. Asset Management

– Over the years we have derived entire disciplines to help define the best ways to care for those assets through their lives and as such we have been Managing Assets for ever.

– Managing Assets (things you do to assets) can be done with or without a structured organizational strategy and context. An organization gains more value from this activity within a context of organizational purpose and strategy that steers this activity (and becomes Asset Management ).

– Asset Management has a broader focus than Managing Assets , encompassing many organizational levels and applying to all functions or departments.

WHY

Montréal’s economy is more vibrant, healthy, and progressive than ever and more international stakeholders in leading-edge sectors are opting for Montréal (Montreal Geared up for Tomorrow, 2018-2022 Economic Development Strategy).

Industry 4.0, public transport, e-commerce or intelligent cities require not only safe but also maximum availability of the existing or new technology, all these combined with a controlled life-cycle cost. In order to achieve these high standards, successful engineers must apply the RAMS concepts all along the life-cycle of a product; but most importantly, they must actively contribute to a major mentality change: RAMS from concept to culture.

If you want to improve reliability and reduce the risk, to reduce the life cycle costs of the product, to improve and protect the brand image by reducing warranty costs and customer complaints, to optimize maintenance strategies, to improve availability or to assess and improve safety, you need the RAMSES Certificate.

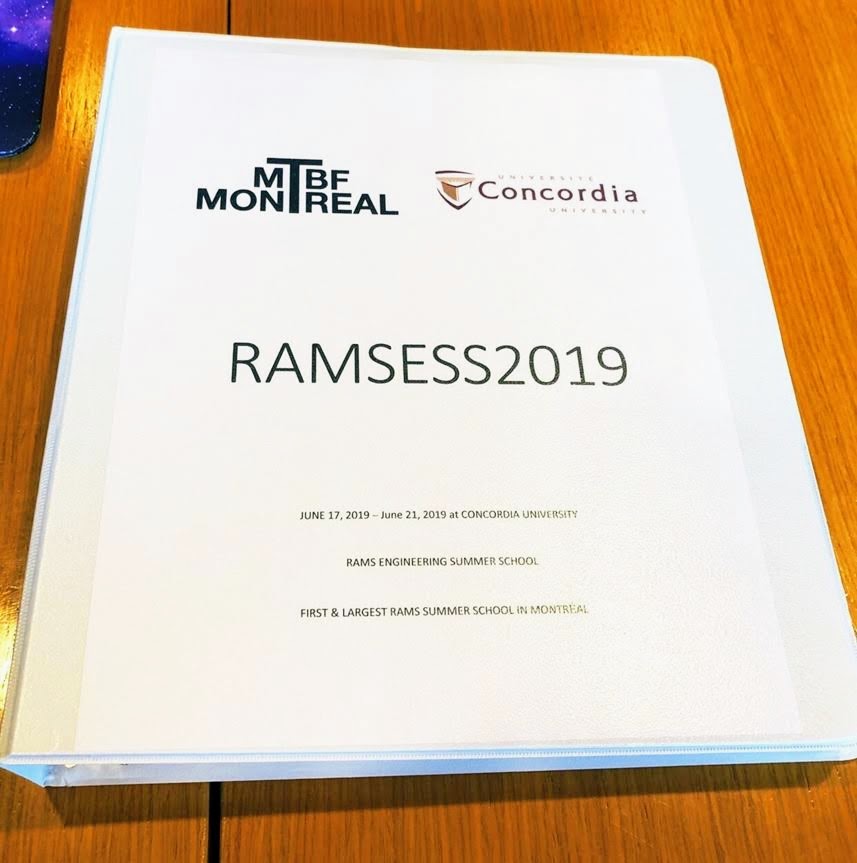

The event is organized by Gina Cody School of Engineering and Computer Science, in partnership with Experts from industry, and focuses on practical aspects and industrial added value. The workshps introduce the RAMS fundamentals and emphases the added-value of each method by examples, case studies, practical aspects of the implementation and a complete set of dedicated tools.

What is Our Goal?

The RAMS Training welcomes industry professionals, graduate students and prospective graduate students to Montreal on each of the 5 Fridays of November. Throughout this program, renowned experts from top Canadian Companies and Concordia University will lead applied workshops in Reliability, Availability, Maintainability and Safety Engineering.

The workshops welcome all professional involved in the life cycle of a product: high management, specialists, integrators, design, development and test engineers, supply chain, maintenance planning, etc., and will be delivered by Concordia faculty members and experienced industry partners.

The Fall RAMS Training is an opportunity for graduate students and industry professionals to advance their skills, network with colleagues and industry partners.

- Become familiar with RAMS definitions and principles and embrace the RAMS culture

- Identify vital RAMS contractual elements

- Integrate RAMS in the current activities and benefit from its added value across industries

- Implement the Design for Reliability techniques in the existing process

- Gain an understanding of the methods, terms and metrics used, when to apply specific tools during different stages of the life cycle

- Assess and optimize system safety

- Optimize a scheduled maintenance plan for a physical asset that will provide an acceptable level of functionality, with an acceptable level of risk, in an efficient and cost-effective manner

- A comprehensive set of dedicated tools