RAMSES certificate

is a must for any engineer (not only RAMS engineers), manager or director. The applied seminars are advocating a transition towards a reliability-focused culture, covering the entire life cycle of a product from inception, through engineering design and validation, manufacture, to entry into service and disposal.WHY

Montréal’s economy is more vibrant, healthy, and progressive than ever and more international stakeholders in leading-edge sectors are opting for Montréal (Montreal Geared up for Tomorrow, 2018-2022 Economic Development Strategy).

Industry 4.0, public transport, e-commerce or intelligent cities require not only safe but also maximum availability of the existing or new technology, all these combined with a controlled life-cycle cost. In order to achieve these high standards, successful engineers must apply the RAMS concepts all along the life-cycle of a product; but most importantly, they must actively contribute to a major mentality change: RAMS from concept to culture.

If you want to improve reliability and reduce risk, to reduce the life cycle costs of the product, to improve and protect the brand image by reducing warranty costs and customer complaints, to optimize maintenance strategies, to improve availability or to assess and improve safety, you need the RAMSES Certificate.

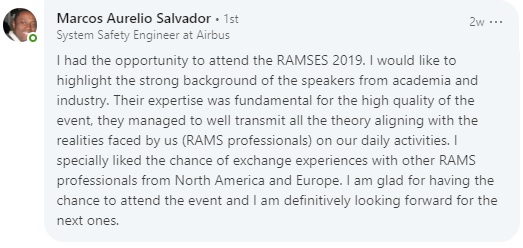

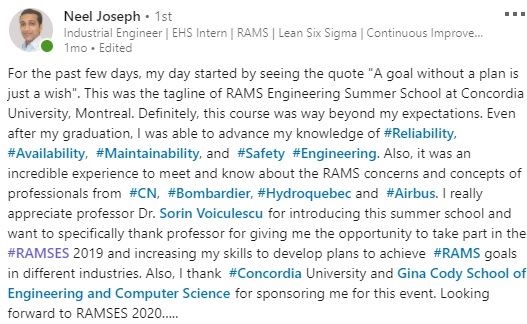

The school is organized by Gina Cody School of Engineering and Computer Science, in partnership with Experts from industry, and focuses on practical aspects and industrial added value. The seminars introduce the RAMS fundamentals and emphases the added-value of each method by examples, case studies, practical aspects of the implementation and a complete set of dedicated tools.

What is Our Goal?

The Fall RAMS Training welcomes industry professionals, graduate students and prospective graduate students to Montreal on each of the 5 Fridays of November. Throughout this program, renowned experts from top Canadian Companies and Concordia University will lead applied seminars in Reliability, Availability, Maintainability and Safety Engineering.

The seminars welcome all professional involved in the life cycle of a product: high management, specialists, integrators, design, development and test engineers, supply chain, maintenance planning, etc., and will be delivered by Concordia faculty members and experienced industry partners.

The Fall RAMS Training is an opportunity for graduate students and industry professionals to advance their skills, network with colleagues and industry partners.

- Become familiar with RAMS definitions and principles and embrace the RAMS culture

- Identify vital RAMS contractual elements

- Integrate RAMS in the current activities and benefit from its added value across industries

- Implement the Design for Reliability techniques in the existing process

- Gain an understanding of the methods, terms and metrics used, when to apply specific tools during different stages of the life cycle

- Assess and optimize system safety

- Optimize a scheduled maintenance plan for a physical asset that will provide an acceptable level of functionality, with an acceptable level of risk, in an efficient and cost-effective manner

- A comprehensive set of dedicated tools